World-Class, Custom

Rotational Molder

-

Trusted Partner

We take pride in our sense of duty to each other and our trusted partners.

-

Talented Team

Our talented team of expert rotomolders are committed to our customers and each other.

-

Total Solution

We develop our team by continuously improving our processes together to exceed customer expectations.

The T3 Difference

Premium Plastic Products

We are committed to bringing the best products to market through high levels of service, the latest technology and innovation.

Our foundation is set on hard work, friendly customer service and dedicated roto-molding professionals that take pride in their work.

About Our Company

We are an experienced rotational molding manufacturer focused on our customers success. Our purpose is to manufacture your designs into high-quality plastic parts. Whether you are new to roto-molding or looking for a new molder of an existing part, we can help with all aspects of the project–from design, mold build, and manufacturing to assembly and shipping. We cover it all!

150

Years Combined

Experience

ISO

9001:2015

Certified Company

90,000

State-of-the-Art

Square Foot Facility

11 FT

Maximum Custom

Part Size

Got an idea for something complex?

We have what you need.

Our expert team of talented rotomolders are ready for your ideas. We’ll be here every step of the way! You deserve a dedicated partner to get the job done.

Project Management

Our team is committed to bringing your products to market through high levels of service, latest technology, and innovation.

Rotational Molding

With a diverse customer base and world-class equipment, our experts are ready to mold products up to 136 inches.

Foaming & Printing

Trained foam technicians can provide both in-process and

post-mold foaming and printing.

Trim and Assembly

T3 can efficiently perform these value-added steps that can streamline your supply chain and help control your costs.

Logistics

Our midwest location is a benefit. T3 arranges freight timely and orderly, ensuring your product ships quickly and efficiently.

Mold Enhancements & Maintenance

In-house maintenance and mold repair ensures molds are properly maintained and ready to make the highest quality products possible.

“T3 is composed of traditionally tactful and thought provoking teammates. Our values include putting in the hard work and sweat to see every custom order completed timely. We thrive on ensuring that all the moving parts come together to transform new ideas into tangible reality. Treat each interaction, meeting, and connection with positivity and purpose.

That’s who we are.”

Our Experience • T3 Manufacturing

T3 Materials make a difference.

Expand each material to learn more!

-

Flexible polyurethane foam is used as cushioning for a variety of consumer and commercial products, including bedding, furniture, automotive interiors, carpet underlay and packaging. Flexible foam can be created in almost any variety of shapes and firmness. It is light, durable, supportive, and comfortable.

-

Rigid polyurethane and polyisocyanurate (polyiso) foams create one of the world's most popular, energy-efficient and versatile insulations. These foams can significantly cut energy costs while making commercial and residential properties more efficient and comfortable.

-

Linear Low Density Polyethylene is extremely durable, while being forgiving and easier to mold via the rotomolding process. Certified prime virgin LLDPE materials can be resistant to chemicals and environmental stress cracking. LLDPE can be dryblended to virtually any color through blending the material with the proper pigments for the rotomolding process.

-

Medium Density and High Density Polyethylenes provide stiffness properties. It features fantastic molding properties for the rotational molding process. Like LLDPE, MDPE and HDPE must be pulverized to a powder or extruded into micropellets for the material to be rotomolded. Quality minded molders generally process MDPE and HDPE with UV stabilizers and AO additives.

-

Cross-Linked Polyethylene contains a special cross-linking agent which reacts with the polymer material throughout the rotomolding process, creating a cross-linked molecule, very similar to a thermoset material. This chemical reaction during the rotomolding process enhances the strength, durability, environmental stress-crack resistance and tear resistance. However, because of this chemical reaction, XLPE products are not capable of being recycled.

-

PVC is extraordinarily versatile with excellent weathering and aging characteristics. It is highly resistant to certain chemicals. PVC grades can be selected for flexibility, impact and temperature performance. Because of their elastomeric qualities, the softer grades of PVC are commonly used where rubber like qualities are required.

Why Rotational Molding?

I'm having difficulties getting my products in on time.

Never worry again about getting your products on time. At T3 we provide same day quotes and offer best-in-class capacity to get your job done quickly.

Get quality and quantity – don’t settle for one or the other.

Rotomolded parts are far superior in durability to their counterparts. You’ll see the difference with T3 rotomolded products with quick lead times and capacity to fit your jobs – now. Our tools and molds are made in a timely fashion (Not 14 weeks!)

Is rotational molding the best for custom designs?

Rotational Molding allows for maximum versatility – perfect for custom designs. Give us your custom and complex. We’ll use the simple and versatile process of rotational molding to make it happen.

Can’t find the answer you’re looking for?

Reach out to our customer support team.

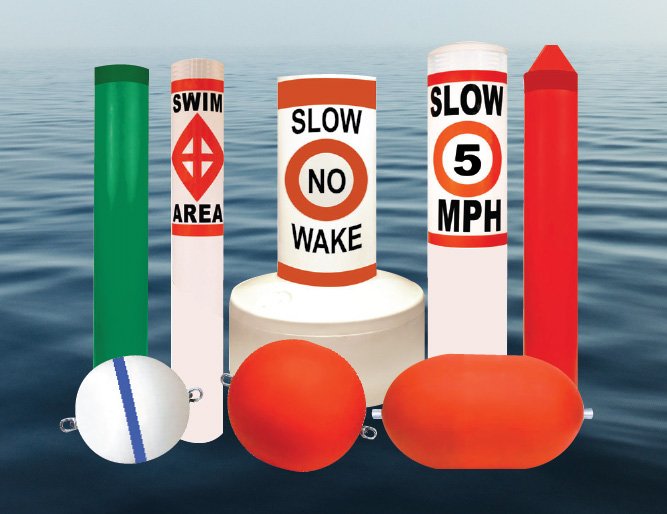

Industries We Serve

Agriculture

Construction

Consumer Goods

Industrial

Marine

Recreation

Tanks

Transportation

Ready to talk? let’s get it done.

T3 is waiting for you.

-

Capacity

You are the priority.

We’ll get your jobs done fast. -

Same Day Quotes

We take customer service seriously.

Same-day quotes, no waiting around for answers. -

Customized Options

Let your creativity run wild!

Our experts help you create, design, and develop your plastic products from start to finish.

Request a Quote

Our expert team of talented rotomolders are ready for your ideas. We’ll be there every step of the way.

Contact information

Phone Number

(920) 631-2101

sales@t3mfg.com

Address

333 Beichl Avenue

Beaver Dam, WI 53916 USA

Come grow with us at T3!

No matter what your role or passion is, you may be who we’re looking for.